Key Advantages

Ultra‑Fine Filtration

The 0.03 µm micropores efficiently remove suspended solids, bacteria and persistent organic pollutants ensuring top-tier effluent quality.

Superior Structural Integrity

Reinforced PVDF fibers resist breakage, peeling and deformation ideal for long-term, reliable operation.

Operational Flexibility

Seamlessly adapts to varied wastewater types and fluctuating pH conditions providing consistently high flux rates.

Eco‑Efficient Design

High flux and robust fouling resistance minimize energy consumption, maintenance demands and operational costs.

Details About MBR Membrane

- Trusted quality – Backed by technical expertise and proven results

- Fully Customized Membrane Solutions

- Perfect Fit for Your Applications

- 100% Assured Quality

- End-to-End Solutions for Wastewater Management

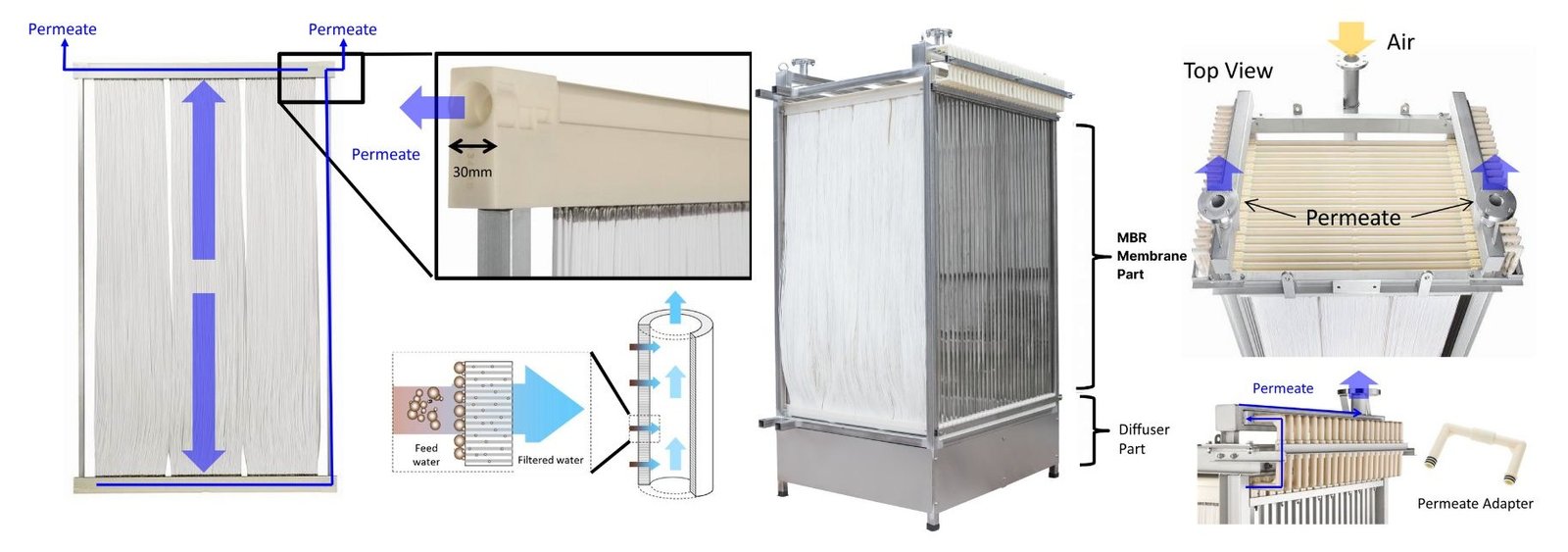

NEYA M SERIES MBR Membrane Working Principle

Neya Membrane Models List

| Model | NEYA M-10 | NEYA M-15 | NEYA M-20 | NEYA M-25 | NEYA M-40 |

| Effective area(m²) | 10 | 15 | 20 | 25 | 40 |

| Size: H*L*W(mm) | 1300*680*30 | 1500*680*30 | 1300*1250*30 | 1500*1250*30 | 2000*1250*30 |

| Flux rate (L/m².hr) | 15~30 | 15~30 | 15~30 | 15~30 | 15~30 |

| Membrane Material | RPVDF + ABS | RPVDF + ABS | RPVDF + ABS | RPVDF + ABS | RPVDF + ABS |

| Supporting Material | SUS 304 | SUS 304 | SUS 304 | SUS 304 | SUS 304 |

| Pore Size (μm) | 0.03 - 0.04 | 0.03 - 0.04 | 0.03 - 0.04 | 0.03 - 0.04 | 0.03 - 0.04 |

| Fiber Diameter (mm) | 2.0 ± 0.025 | 2.0 ± 0.025 | 2.0 ± 0.025 | 2.0 ± 0.025 | 2.0 ± 0.025 |

| Bubble Point (Mpa) | >0.05 | >0.05 | >0.05 | >0.05 | >0.05 |

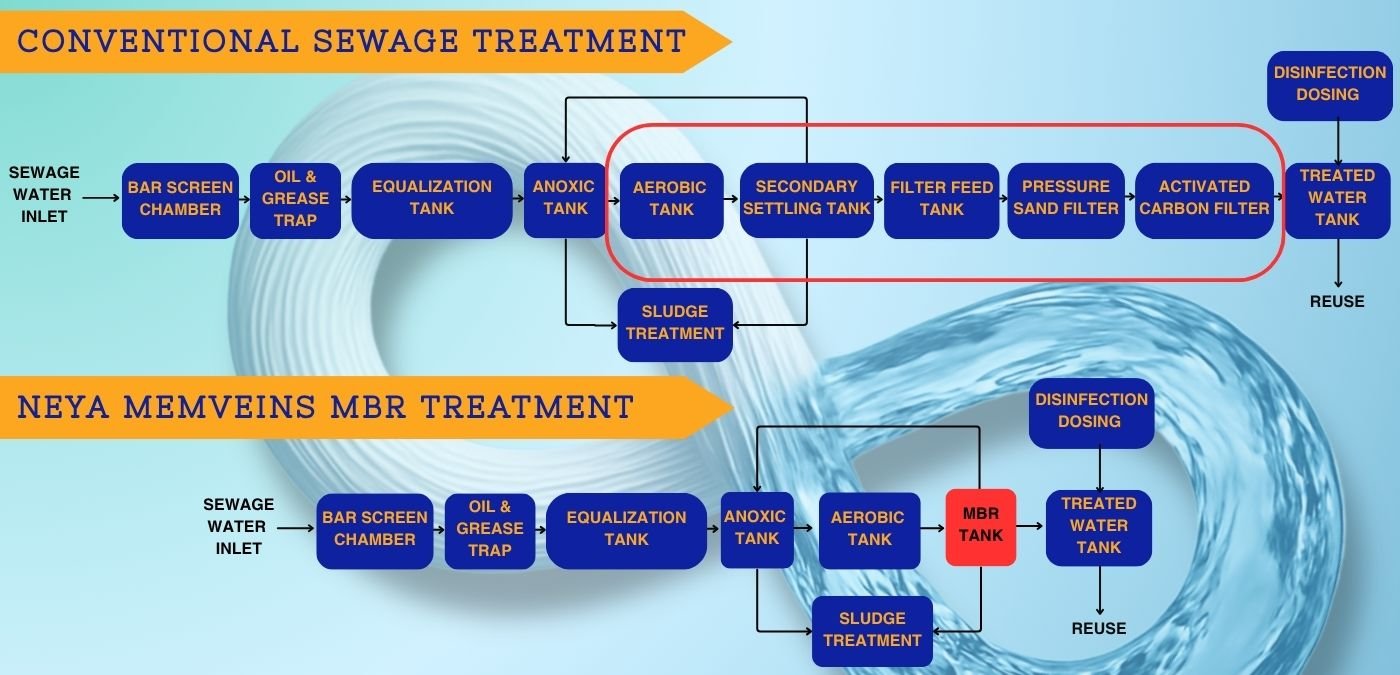

Waste Water Treatment Process Comparison

Characteristics of the Raw and Treated Sewage Water

| Index | Raw Sewage Water | Treated Water (At outlet of Conventional System) | Treated Water (At outlet of NEYA Memveins MBR System) |

|---|---|---|---|

| pH | 6.5 -7.5 | 6.5 -7.5 | 6.5 -7.5 |

| COD | ≤ 400 - 600 ppm | ≤ 100 ppm | ≤ 50 ppm |

| BOD (3 days @ 27 ˚C) | ≤ 250 - 350 ppm | ≤ 30 ppm | ≤ 10 ppm |

| TSS | ≤ 200 ppm | ≤ 30 ppm | ≤ 1 ppm |

| Oil & Grease | ≤ 30 ppm | ≤ 20 ppm | ≤ 10 ppm |

| Turbidity ( NTU ) | >100 | <20-25 | ≤ 1 ppm |

Applications

Municipal water supply

Industrial water purification

Boiler feed water, cooling water

Pharmaceutical manufacturing

Municipal waste water treatment

Reclaimed water reuse

Local sewage plants

Water processing and recycling facilities

Pretreatment process for drinking water

Pretreatment process for RO system

Landfill leachate advanced treatment

Module Options & Customisation

Available in various capacities, featuring SS304 or UPVC frames, PET-lined PVDF fibers and complete permeate/aeration piping—fully customizable to meet your project’s unique specifications.

Company & System Integration

- Manufactured by Neya Memveins Technologies

- Widely deployed across global MBR projects, delivering impressive membrane treatment capacity exceeding 24,000 m²/month

Why Choose Neya M Series MBR Membrane?

Exceptional Effluent Quality

Reaches near-zero TSS and bacterial levels the gold standard in MBR.

Low Fouling, High Reliability

Robust construction minimizes blockage and keeps operational costs low.

Adaptable &

Compact

Perfect balance of high flux, chemical tolerance and small footprint.

Precision Engineering

Reinforced PVDF fibers (PET liners + SS/UPVC support) ensure exceptional durability, unmatched structural strength, and long-term reliability.

Local Manufacturing & Expertise

Manufactured in Ahmedabad, Gujarat, India, with end-to-end support from design and installation to operations, maintenance, and troubleshooting.