How MBR Technology Works with NMV SERIES Membranes

A MBR system, powered by our NMV SERIES Hollow Fiber RPVDF Membranes, primarily consists of a bioreactor and a membrane module. Here’s a breakdown of its functionality:

Bioreactor Stage

Sewage or wastewater first enters the bioreactor, where pollutants undergo degradation by a rich community of microorganisms. This biological treatment significantly reduces the organic load (BOD, COD) and prepares the water for subsequent membrane filtration.

Membrane Module Integration

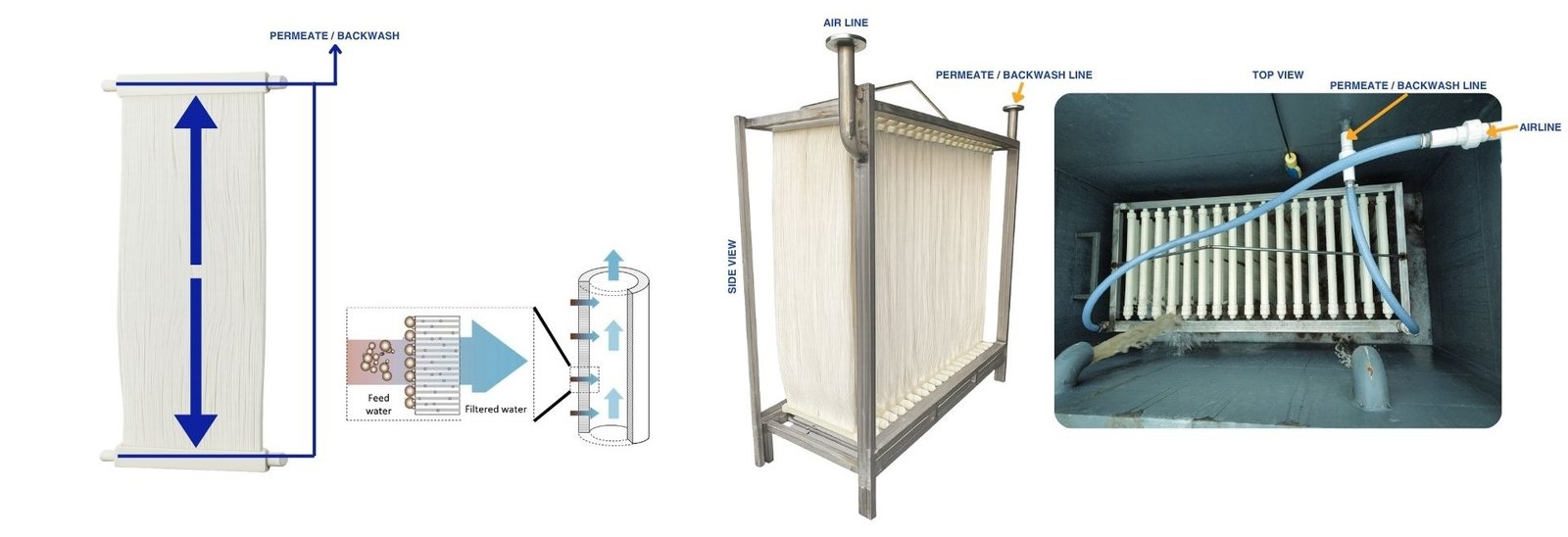

The NMV SERIES Hollow Fiber Membrane module is strategically integrated to intercept microorganisms and effectively filter the effluent. The unique design of our hollow fiber membranes allows water to permeate through tiny pores, while activated sludge and other contaminants are efficiently retained within the tank. This process dramatically enhances the system’s capacity to degrade pollutants and ensures a high level of purification.

Key Advantages

Stable and Excellent Water Quality

The advanced filtration capabilities ensure a consistently high quality of treated water.

Superior Structural Integrity

Reinforced PVDF fibers resist breakage, peeling and deformation ideal for long-term, reliable operation.

Operational Flexibility

Seamlessly adapts to varied wastewater types and fluctuating pH conditions providing consistently high flux rates.

Eco‑Efficient Design

High flux and robust fouling resistance minimize energy consumption, maintenance demands and operational costs.

Ultra‑Fine Filtration

The 0.03 µm micropores efficiently remove suspended solids, bacteria and persistent organic pollutants ensuring top-tier effluent quality.

Water Reuse Potential

The purified water is suitable for various potable purposes including flushing, gardening and irrigation, curing and car washing promoting sustainable water management practices.

Details About MBR Membrane

- Trusted quality – Backed by technical expertise and proven results

- Tailored to Your Requirements – Designed to fit your specific system needs

- 100% Quality Assured – Every unit meets strict performance standards

- Reliable for Every Project – Built for durability, efficiency and ease of integration

- End-to-End Solutions for Wastewater Management

NEYA NMV SERIES MBR Membrane Working Principle

Neya Membrane Models List

| Model | NMV-10 | NMV-20 | NMV-30 |

|---|---|---|---|

| Effective area(m²) | 10 | 20 | 30 |

| Size: H*L*W(mm) | 1000*535*46 | 1500*535*46 | 2000*535*46 |

| Flux rate (L/m².hr) | 15~30 | 15~30 | 15~30 |

| Membrane Material | RPVDF + ABS | RPVDF + ABS | RPVDF + ABS |

| Connector | ABS | ABS | ABS |

| Pore Size (μm) | 0.03 - 0.04 | 0.03 - 0.04 | 0.03 - 0.04 |

| Fiber Diameter (mm) | 2.0 ± 0.025 | 2.0 ± 0.025 | 2.0 ± 0.025 |

| Bubble Point (Mpa) | >0.05 | >0.05 | >0.05 |

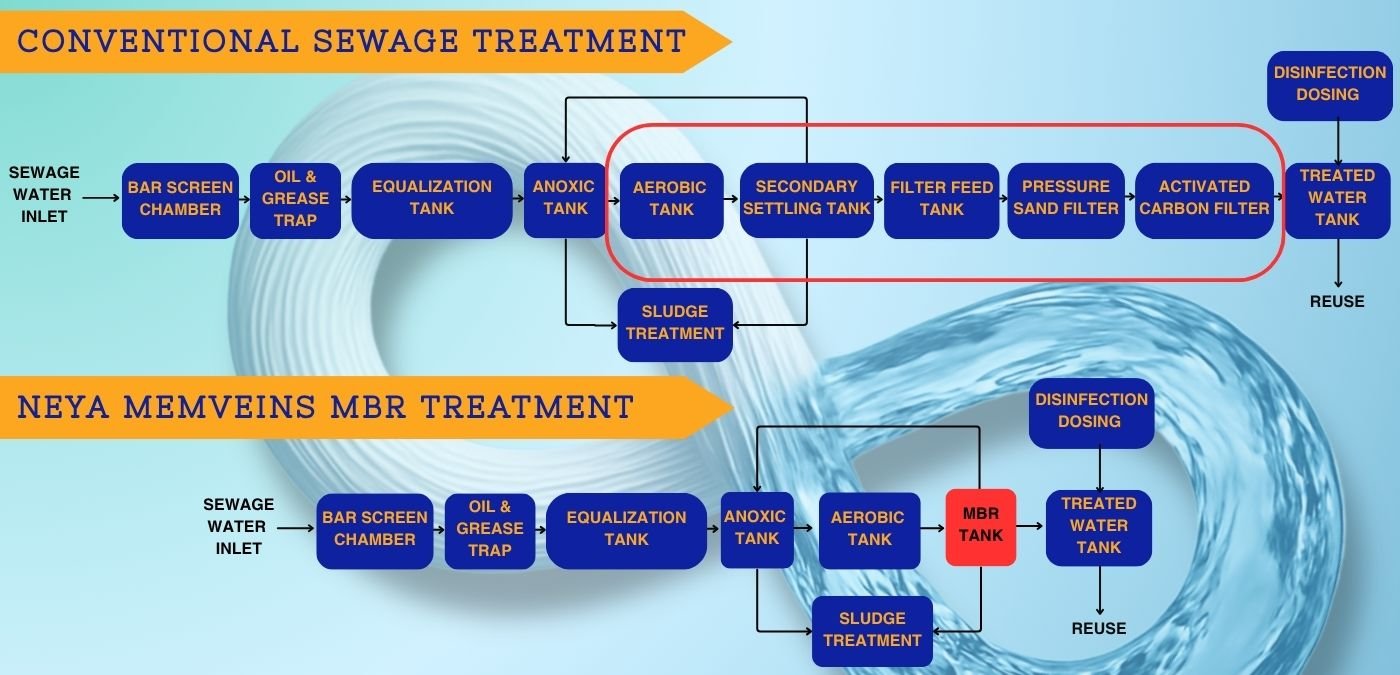

Waste Water Treatment Process Comparison

Characteristics of the Raw and Treated Sewage Water

| Index | Raw Sewage Water | Treated Water (At outlet of Conventional System) | Treated Water (At outlet of NEYA Memveins MBR System) |

|---|---|---|---|

| pH | 6.5 -7.5 | 6.5 -7.5 | 6.5 -7.5 |

| COD | ≤ 400 - 600 ppm | ≤ 100 ppm | ≤ 50 ppm |

| BOD (3 days @ 27 ˚C) | ≤ 250 - 350 ppm | ≤ 30 ppm | ≤ 10 ppm |

| TSS | ≤ 200 ppm | ≤ 30 ppm | ≤ 1 ppm |

| Oil & Grease | ≤ 30 ppm | ≤ 20 ppm | ≤ 10 ppm |

| Turbidity ( NTU ) | >100 | <20-25 | ≤ 1 ppm |

Ideal Applications

Municipal water supply

Industrial water purification

Boiler feed water, cooling water

Pharmaceutical manufacturing

Municipal waste water treatment

Reclaimed water reuse

Local sewage plants

Water processing and recycling facilities

Pretreatment process for drinking water

Pretreatment process for RO system

Landfill leachate advanced treatment

Module Options & Customisation

Available in various capacities featuring SS304 or UPVC frames, PET-lined PVDF fibers and complete permeate/aeration piping—fully customizable to meet your project's unique specifications.

Supply & Delivery

Extensive Distribution Network

Seamless delivery backed by advanced infrastructure in Ahmedabad, Gujarat, India serving domestic and global needs.

Trusted Warranty

Our robust standard warranty ensures long-term reliability and confidence.

Swift Turnaround

Membranes are efficiently manufactured for dispatch soon after production completion.

Packaging & Logistics

Carefully packed to protect your modules during transit with reliable handling.

Why Choose Neya NMV Series MBR Membrane?

Tailored Support

At NEYA, we don’t believe in a “one-size-fits-all” approach. Our flexibility allows us to assess your unique needs and deliver the most apt and cost-efficient solution from basic equipment supply to comprehensive plant design and construction. Every project is approached with precision, innovation and a commitment to long-term value.

Global Standards

At Neya Memveins Technologies, our MBR membranes are built to the highest international standards, ensuring durability, safety and compatibility across diverse applications. With strict testing and certifications, we deliver consistent performance that meets the evolving needs of industries worldwide from wastewater treatment to large-scale infrastructure projects.

In‑house High‑Tech Manufacturing

With extensive hands-on experience and advanced in-house capabilities, our team combines practical knowledge with cutting-edge technology to design and manufacture high-performance wastewater treatment systems. Our high-tech facility empowers us to select, engineer and deliver the most efficient, application-specific solutions for every project.

High Standards of Quality and Safety

All projects at NEYA are carried out under comprehensive quality assurance and safety systems. Our wastewater treatment equipment is manufactured to ISO:9001 standards of safety and design. We recognise the importance of Safety & Quality to our clients and adhere to the strictest and most transparent policies.

Innovation, Sustainability and Global Reach

Neya Memveins Technologies is committed to continuous innovation, leveraging advanced technology and extensive Research and Development to anticipate and meet evolving market demands. Our membranes are engineered using sustainable materials, reflecting our commitment to environmental responsibility. This focus on sustainability, coupled with measurable advantages in efficiency, longevity and cost-effectiveness makes our membranes the ideal choice for communities and industries worldwide.

We proudly serve a growing network of domestic and international markets, supported by a robust distribution network in key regions. Our adherence to rigorous quality standards is underscored by relevant certifications, ensuring that our products not only perform exceptionally but also comply with global regulatory requirements.

Choose Neya Memveins Technologies for membrane solutions that deliver unparalleled performance, foster sustainability and drive efficiency. Experience the future of filtration with the NMV SERIES Hollow Fiber Membrane.